Types of stations in the transportation (midstream) of natural gas by pipeline: injection point, compression, metering, regulation, and control centers.

May 29, 2025.

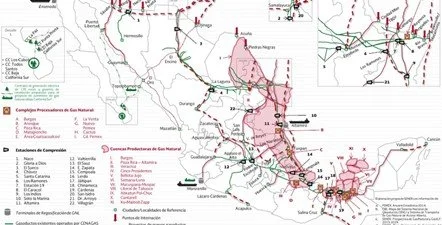

Figure 1. National Gas Pipeline System (SNG). (CENAGAS, 2016)

The transportation of natural gas through pipelines is a highly technical process that requires not only an extensive network of pipes but also the integration of key stations that allow for the control, measurement, and assurance of the safe and efficient flow of gas over hundreds or even thousands of kilometers.

Below are explanations of the three fundamental stations in any natural gas transportation system: compression, metering, and regulation. Additionally, injection points and control centers, essential to its operation, are included.

1. Compression Stations: Driving the Flow

Figure 2. Compression Station. (AI-generated)

These stations are crucial for maintaining gas pressure along the pipeline, as the gas is periodically compressed to compensate for pressure losses during transportation. These stations, also known as pumping stations, ensure the continuous and efficient flow of gas through the pipeline network.

As natural gas travels through the pipelines, it loses pressure due to friction and changes in topography. Compression stations are responsible for maintaining adequate pressure, allowing the gas to continue its journey toward consumption centers.

Main functions:

Increase gas pressure using centrifugal, reciprocating, or screw compressors.

Enable modular operations with multiple compression trains.

Incorporate aftercooling systems to control gas temperature after compression.

Long-distance transport: Facilitate the movement of natural gas from production sites to storage centers or end users over large distances.

Typical components of a compression station:

Compressors: The heart of the station, which can include turbines, engines, or electric-driven compressors—centrifugal, reciprocating, or screw types.

Cooling system: Compression raises the gas temperature, so cooling systems are needed to prevent damage to the pipeline.

Filters: Used to remove water, impurities, and other contaminants from the gas.

Control systems: Monitor and regulate pressure, temperature, and other station parameters.

Control systems: Used to monitor and regulate pressure, temperature, and other parameters of the station.

Importance of the compression station:

Transport efficiency: Ensure that natural gas is transported efficiently and continuously.

Safety: Help maintain proper pressure to prevent risks in the pipeline.

Long-distance distribution: Enable natural gas to be transported over long distances, from production points to consumers.

Engineering considerations:

For the design of compression stations, the following factors are considered:

Power required according to hydraulic simulations.

Selection of compressors, valves, and control systems.

Integration of the system into 3D models for multidisciplinary review.

2. Metering stations: precision at every moment

Metering stations allow the quantification of the volume of gas flowing through the pipeline, which is essential for both commercial and regulatory purposes. A natural gas metering station in the midstream sector is a facility used to measure the flow and pressure of natural gas along a pipeline. These stations are crucial for the transportation and storage of natural gas in the midstream segment of the supply chain.

Figure 3. Metering station. (COIMSUR, 2019)

Main functions:

Flow measurement: Metering stations measure the amount of gas flowing through the pipeline, allowing the calculation of the energy being transferred.

Pressure regulation: Metering stations also regulate the gas pressure, ensuring it remains within the appropriate limits for efficient transportation through the pipeline.

Gas quality control: Some metering stations may also include equipment to analyze the gas quality, such as H2O and H2S analyzers and gas chromatographs, to identify any impurities that may affect its transport or consumption.

Typical components of a metering station:

Straight pipe sections: These are the sections of pipe upstream and downstream of the primary element (flow meter) in the metering system, which include flow conditioners or aligners according to the technology used.

By-pass valves: Used for maintenance on the relevant section, such as the regulation system, filtering system, or control system.

Instrumentation associated with the metering system: The instruments associated include PIT (pressure transmitters), TIT (temperature transmitters), and FIT (flow transmitters), which are used for flow calculation and its corrections for pressure and temperature.

Chromatography: Used for composition analysis and calorific value, in addition to performing calculations of gas properties to add those properties to the calculation of the flow, energy, etc.

Filters or filtration systems: These systems are designed to remove contaminants, liquids, and/or solids present in the natural gas being transported. In the case of a metering station, their primary goal is to protect subsequent stages such as measurement, regulation, or delivery to the user (downstream). They have block valves and by-pass valves for maintenance.

Flow meters: Responsible for quantifying the fluid flowing through the system. In the case of natural gas, the following meters may be used: ultrasonic (for high flow rates and low pressure drop), turbine or orifice (under controlled conditions), or positive displacement.

Gas quality: H2O, H2S analyzers, and gas chromatographs are used to determine the physicochemical properties of natural gas, contributing to the calculation of flow, energy, and more.

Control room: This contains the flow computer, where all signals from the instruments associated with the metering system (both primary and secondary elements) are received. The tertiary element (flow computer) is responsible for performing flow calculations, making corrections, and sending this information to the SCADA system.

Importance of the metering station:

Precise measurement: They allow accurate gas measurement, which is crucial for billing and energy management.

Quality control: They help ensure the quality of the gas, preventing issues in distribution (downstream) and consumption.

Engineering documents:

The engineering documents that are widely used for operation are the following:

P&ID, piping and instrumentation diagram

Operational philosophy

Plant and/or equipment layout

Isometrics

The design of the metering station must be based on the standards that apply, depending on the measurement technology and the regulatory body. These may include AGA, API, ASME, RES/776, NOM-007, etc.

3. Regulation stations: control and safety

Natural gas regulation stations are essential facilities within the midstream sector, as they are responsible for reducing and stabilizing the pressure of the gas before it is delivered to distribution areas (downstream) or industrial users. Their main function is to ensure a safe and efficient supply by controlling the pressure within the network, so the gas reaches end consumers under the proper conditions. In this way, these stations play a key role in the proper functioning of the natural gas transportation and distribution system.

Figure 4. Regulation station. (COIMSUR, 2019)

Main function:

Protect downstream networks against overpressure.

Reduce and stabilize the pressure of natural gas: The regulation station reduces the high pressure of natural gas transported through pipelines to a more suitable pressure for distribution to customers, such as homes, businesses, and industries.

Maintain constant pressure: The station uses pressure regulators to maintain a constant output pressure, regardless of variations in the input pressure or gas flow.

Ensure gas quality: The station may include filters to remove impurities from the natural gas, ensuring that the gas being distributed is of high quality.

Typical components of a regulation station:

Pressure regulators: Devices that control and reduce the pressure of the gas; they can be automatic or pilot-operated.

Indicators and/or transmitters of Pressure

Safety devices: Safety valves (PSV) and venting systems.

Gas filtration: Used to prevent the entry of impurities into the gas.

Importance of the regulation station:

The midstream sector is responsible for the transportation, storage, and processing of natural gas. Regulation stations are an integral part of this process.

These stations ensure that natural gas reaches customers at the correct pressure and quality, which is essential for the efficient operation of distribution systems.

4. Injection and import point

Figure 6. Pipeline systems. (Secretaría de Energía,2016)

These points, such as Reynosa, Arguelles, Altamira (LNG), and Manzanillo (LNG), are where natural gas enters the pipeline transportation system, either through pipelines or by importing Liquefied Natural Gas (LNG).

5. Control centers

Figure 6. SCADA system. (SICCOA, 2018)

These centers oversee the operation of the transportation system, monitoring the pressure, flow, and quality of the gas, and taking measures to ensure its safety and efficiency.

Good design = safe operation:

From the basic engineering stage, this equipment is integrated with the client's SCADA systems, and all specifications are defined to ensure their reliable operation.

Example: National Gas Pipeline System (SNG)

The National Gas Pipeline System (SNG) has a length of 8,610.797 km, crossing various states of the country. The system consists of pipelines ranging from 4" to 48" in diameter, 9 compression stations with a total installed power of 256,400 (Hp), as well as 359 sectioning valves, 142 pig sending traps, 141 pig receiving traps, and 121 Regulation and Metering Stations (ERM) that distribute natural gas to various users (CENAGAS, 2016)

Figure 7. National Gas Pipeline (SNG) CENAGAS

(CENAGAS, 2018)

Conclusion

Compression, metering, and regulation stations are not just auxiliary elements in a natural gas transportation system: they are critical nodes that ensure pressure, quality, safety, and traceability throughout the entire gas journey.

At MELS – Metrology and Energy, we have experience in the design and integration of these stations, adapting to the specific requirements of each operator, regulations, and geographic environment.

References

Basu, S. (2018). Plant Flow Measurement and Control Handbook. London: Academic Press.

CENAGAS. (5 de SEPTIEMBRE de 2016). CENAGAS . Obtenido de GOBIERNO DE MEXICO: https://www.gob.mx/cenagas/acciones-y-programas/descripcion-general

CENAGAS. (24 de AGOSTO de 2018). CENAGAS. Obtenido de CENAGAS: https://www.facebook.com/photo.php?fbid=710686152626369&id=138231799871810&set=a.138316823196641

COIMSUR. (22 de ABRIL de 2019). COIMSUR. Obtenido de COINSUR: https://www.youtube.com/watch?v=HC0S5sR1Uuk

Secretaría de Energía. (24 de mayo de 2016). Secretaría de Energía. Obtenido de Secretaría de Energía: https://www.gob.mx/sener/articulos/mapa-infraestructura-nacional-de-gas-natural-2016

SICCOA. (2018). SICCOA. Obtenido de SICCOA: https://siccoa.com/index.php/nuestros-proyectos/nuestros-proyectos?amp;view=article&id=117&Itemid=467